| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : HDB

Model Number : Boiler Economizer

Certification : ASME,EN,ISO,SGS

Place of Origin : CHINA

MOQ : 5 Ton

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 500 tons/month

Delivery Time : 30 working days

Packaging Details : Seaworthy Packing

Size : Customized

Application : power plant/WTE/waste incineration

Output : Hot Water/Steam

Fuels : Coal;Oil;Biomass

Material : Carbon steel

Standard : ASME&GB

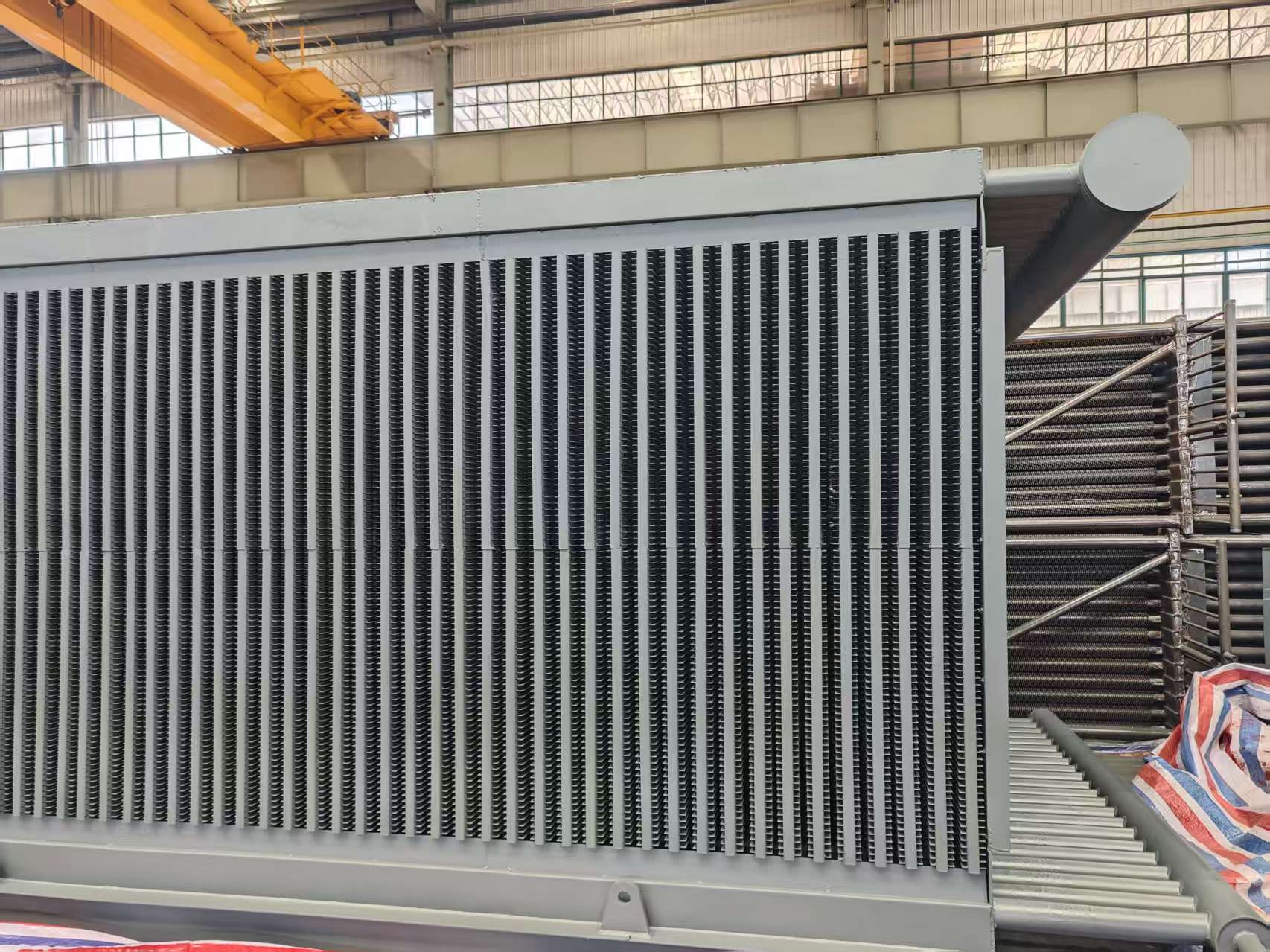

High-Performance Waste Incineration Boiler Economizer With Manifold Headers

How does economizer affect boiler exhaust temperature?

Every 20-25°C reduction in exhaust temp increases efficiency by ~1%.

Economizer description

Function

1. Absorb the heat of low-temperature flue gas, reduce the smoke exhaust temperature, reduce smoke loss and save fuel.

2. Since the feed water is heated in the economizer before entering the drum, the heat absorption of the feed water on the heating surface is reduced, and the economizer can be used to replace part of the high-cost evaporative heating surface.

3. When the feed water temperature is raised, the wall temperature difference will be reduced and the thermal stress will be correspondingly reduced to extend the service life of the steam drum.

Specification

| Description | Boiler economizer |

| Material | Alloy steel, Carbon steel, SA210C , SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton Max.:1000 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

Application

Related Industry: Combined cycle power plant,Heat recovery steam generator(HRSG).

Economizers are commonly used as part of a heat recovery steam generator (HRSG) in a combined cycle power plant. In an HRSG, water passes through an economizer, then a boiler and then a superheater. The economizer also prevents flooding of the boiler with liquid water that is too cold to be boiled given the flow rates and design of the boiler.

|

|

High Performance Waste Incineration Boiler Economizer With Manifold Headers Images |